We Proudly Loud our Wide range of Product Wedge Cutter. The Wedge Cutter is used to break the lengthy runner bars of Ductile & Grey Iron Castings to small pieces, as to accommodate more quantity of runners in the furnace. As a result the power consumption is reduced up to 20%. It includes Hydraulic System, High Class Power backup, Electrical Panel, Heat Exchanger (water cooled) and Wedge Cutter. The tools are made of high wear resistance special tool material. We can provide our patron’s specification and requirements.

Compared to ordinary hammering, plasma cutting and grinding methods, the Snap Breaker provides a faster, safer and easier alternative.

Breaking runners and sprues can now be done easily within seconds.

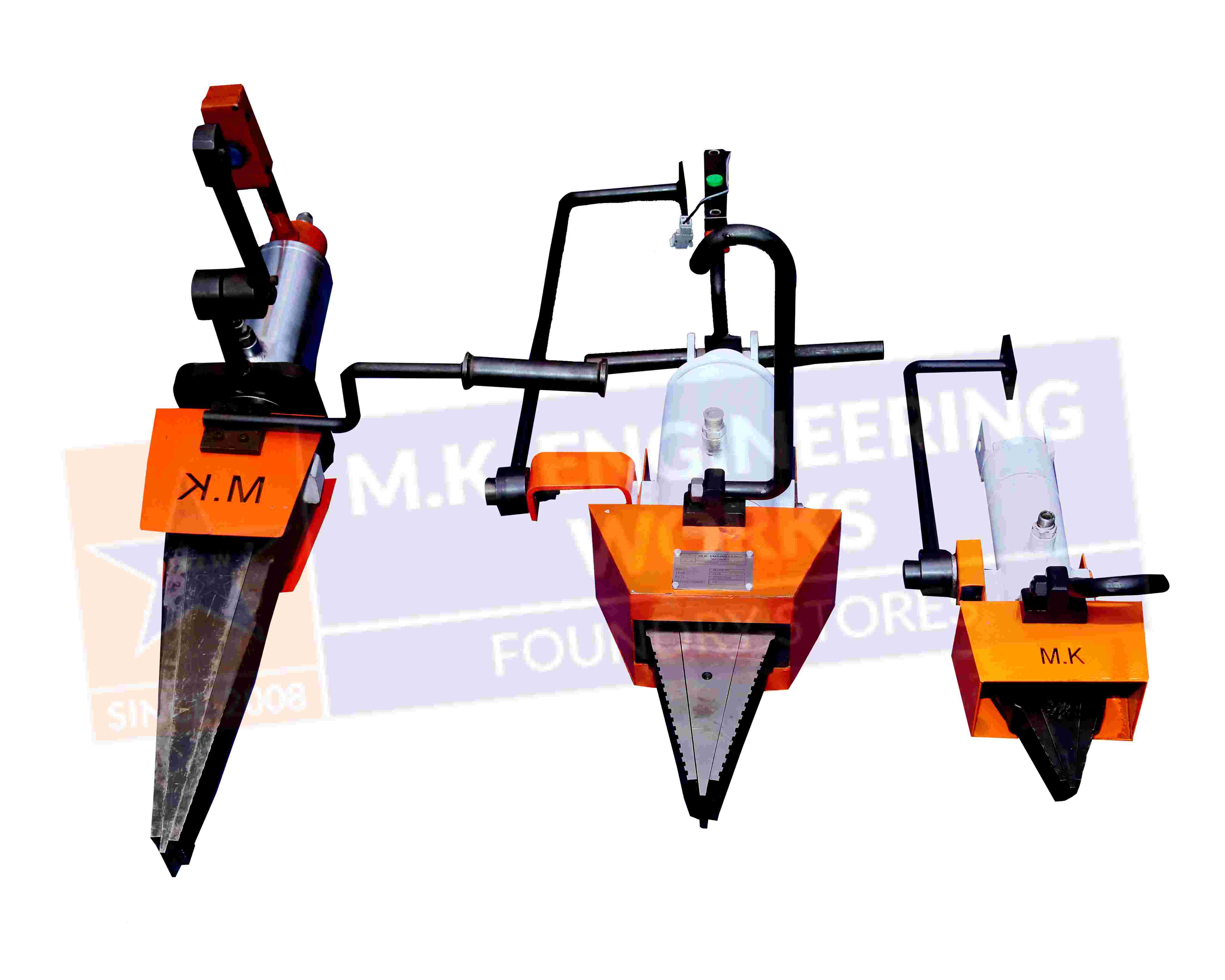

Types of Runner Breaker :

We are the best manufacturer and supplier of wedge cutter in market. And we have some specified models for largest foundry and small scale industries in India.

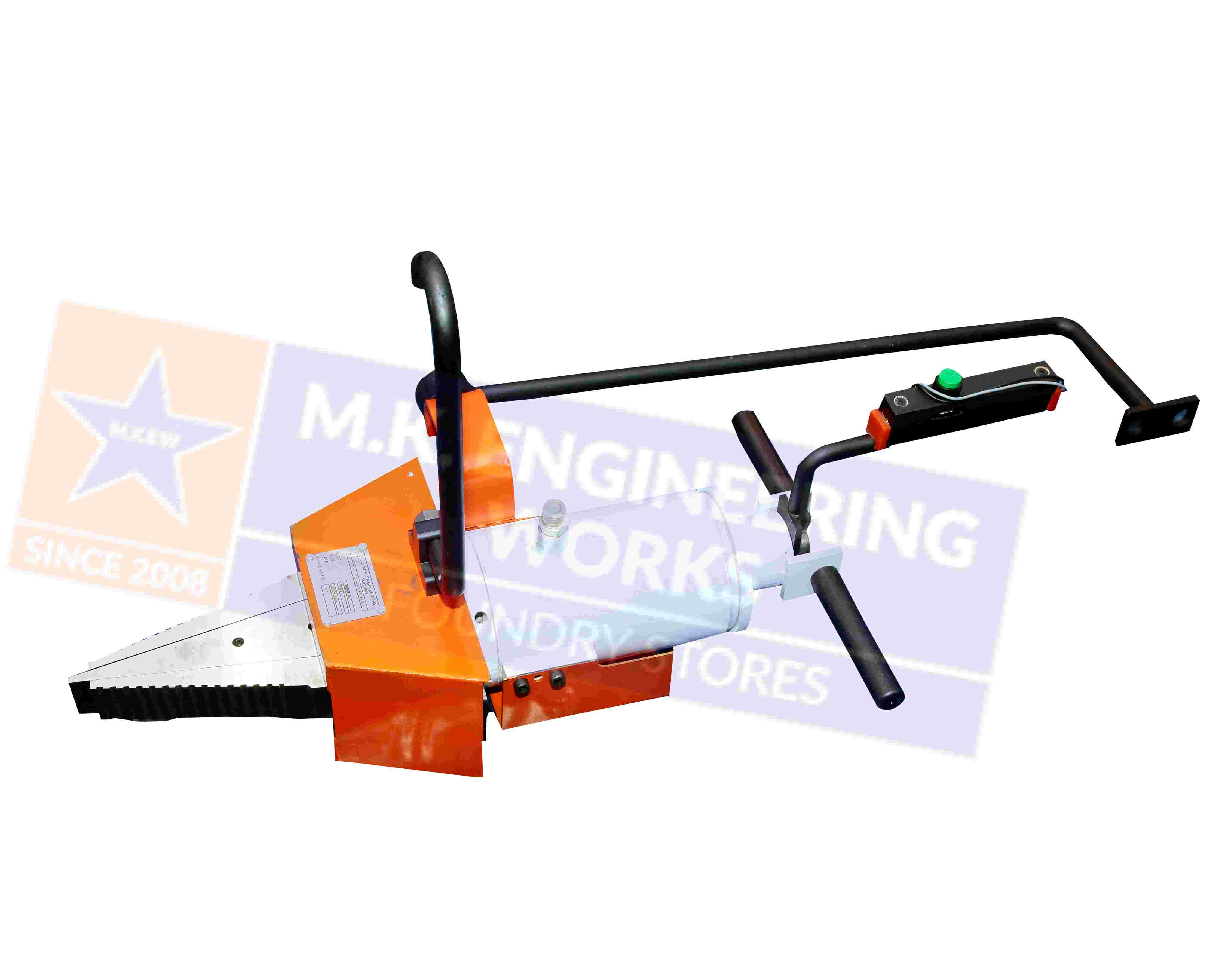

Runner Breaker :

It is essential for breaking down long-sized runners and sprues from ductile and grey iron castings. It aids in efficient handling and recycling of excess material, preparing remnants for melting. By reducing large pieces into manageable sizes, it enhances the melting process, speeding up production and improving operational efficiency. Durable and reliable, the Runner Breaker optimizes foundry workflows and boosts productivity.

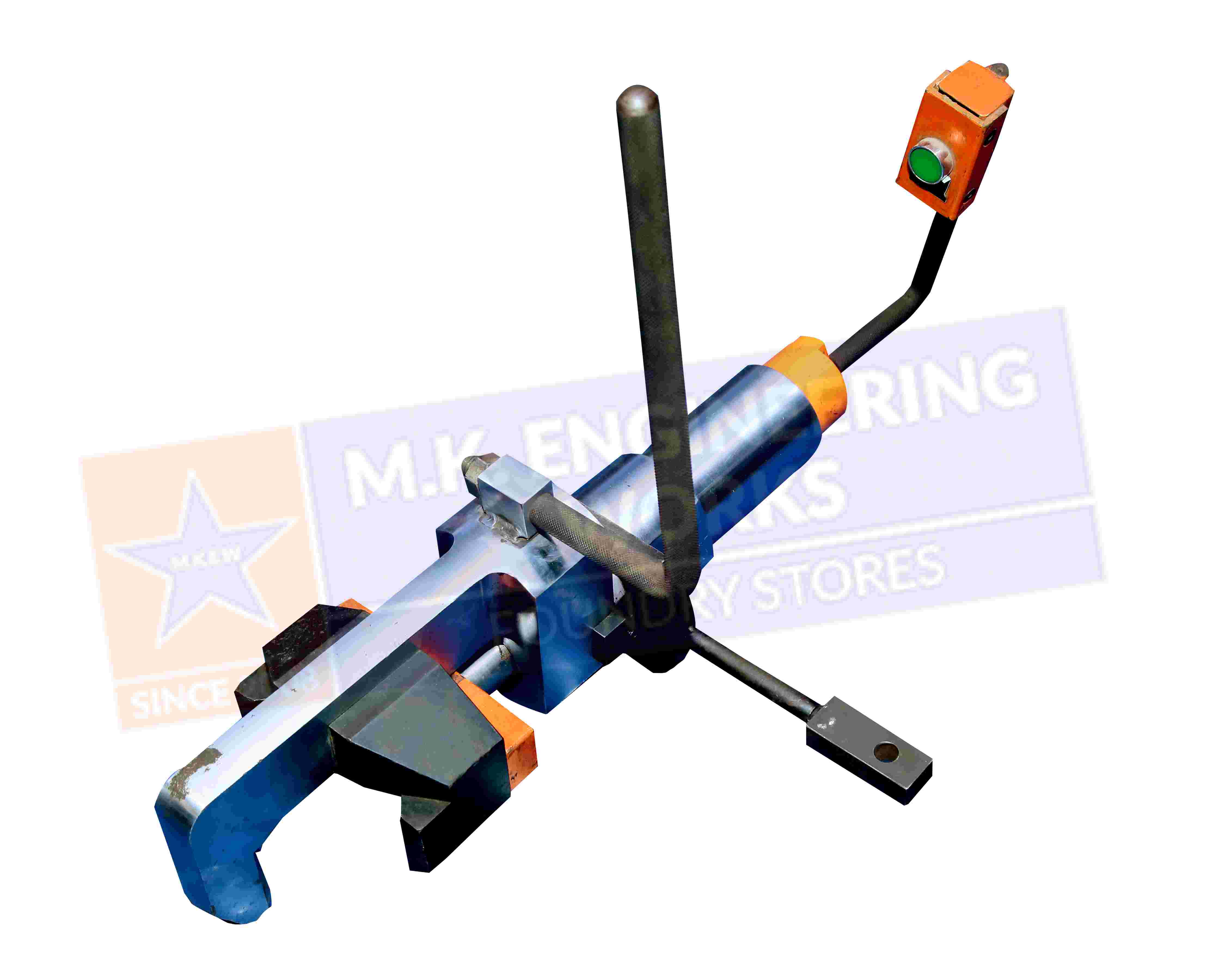

Wedge Cutter :

Our wedge cutter used for splitting gates from iron castings. And it's also known as casting splitter. Wedge cutter provides easier, faster and safer solutions for requirements. Splitter splits the unnecessary parts from the casting safely and easily within seconds and without damage. The wedge cutter is lightweight, compact and fully rotatable, allowing for different angles of splitting.

Runner Cutter :

Our Runner Cutter, featuring a wedge cutter design, is expertly engineered to break down long and high-thickness sprues from ductile and grey iron castings. This robust, table-topped fixed cutter handles the toughest casting materials, efficiently breaking them down in seconds. Its quick operation enhances foundry efficiency by speeding up the recycling and preparation of casting remnants for melting. The Runner Cutter is highly versatile and can be customized to meet specific customer requirements. This adaptability ensures it meets the unique needs of various foundry operations, providing a tailored solution that maximizes productivity. Built for durability and reliable performance, the Runner Cutter is indispensable for optimizing workflows and boosting overall operational excellence.

Our Models of RUNNER BREAKER :

We are introducing our Wedge cutters in multiple size variation. And also our customer can get they own specified sizes. Check out our size variation as follows.

RBHM - 20

RBHM - 40

RBHM - 50

RBHM - 60

RBHM - 80

Features :

Power cost (Melting) - Saving up to 20%

Quick melting

High performance and productivity (1000 breakings/hr)

Easy feeding of runners in to the furnace

Life of furnace linings will be increased

No bridging formation inside the furnace

Features :

Unskilled labour is enough to operate

Low operation cost

Material movement can be minimized

Less physical effort

Labour dependability minimized

Easy positioning and operation

| Model | Length | Width | Breaking Force | Breakable Thickness (Grey) (Reference) | Breakable Thickness (Ductile/Nodular) (Reference) | Max.Gap | Type |

|---|---|---|---|---|---|---|---|

| RBHM-20 | 640mm | 20kg | 121kN | 48mm x 48mm | 30mm x 30mm | 50mm | Handheld |

| RBHM-40 | 781mm | 38kg | 185kN | 55mm x 55mm | 40mm x 40mm | 60mm | Handheld |

| RBHM-50 | 848mm | 65kg | 222kN | 54mm x 54mm | 50mm x 50mm | 56mm | Handheld |

| RBHM-60 | 957mm | 97kg | 397kN | 85mm x 85mm | 55mm x 55mm | 88mm | Handheld |

| RBHM-80 | 1200mm | 170kg | 397kN | 95mm x 95mm | 70mm x 70mm | 100mm | Handheld |

Our Models of WEDGE CUTTER :

We are introducing our Wedge cutters in multiple size variation. And also our customer can get they own specified sizes. Check out our size variation as follows.

WCHM - 16

WCHM - 20

WCHM - 25

WCHM - L25

WCHM - 30

WCHM - L30

WCHM - 40

WCHM - 50

WCHM - 60

| Model | Length | Width | Split Force | Breakable Gate | Opening Width | Wedge Top Width | Wedge Base Width | Wedge Height |

|---|---|---|---|---|---|---|---|---|

| WCHM-16 | 488mm | 8kg | 50kN | 16mm x 16mm | 20mm | 12mm | 60mm | 30mm |

| WCHM-20 | 569mm | 12kg | 72kN | 20mm x 20mm | 30mm | 12mm | 60mm | 31mm |

| WCHM-25 | 526mm | 18kg | 191kN | 25mm x 25mm | 30mm | 12mm | 68mm | 44mm |

| WCHM-L25 | 571mm | 19kg | 191kN | 25mm x 25mm | 30mm | 12mm | 68mm | 44mm |

| WCHM-30 | 526mm | 17kg | 191kN | 30mm x 30mm | 23mm | 12mm | 75mm | 33mm |

| WCHM-L30 | 571mm | 19kg | 191kN | 30mm x 30mm | 23mm | 12mm | 75mm | 44mm |

| WCHM-40 | 735mm | 25kg | 331kN | 40mm x 40mm | 32mm | 15mm | 83mm | 31mm |

| WCHM-50 | 793mm | 31kg | 500kN | 50mm x 50mm | 32mm | 15mm | 90mm | 34mm |

| WCHM-60 | 812mm | 52kg | 682kN | 57mm x 57mm | 32mm | 15mm | 90mm | 55mm |